Products

Your specialist for optimal boiler solutions

Our wide choice of different boiler systems allows the customer to choose the best solution for each facility:

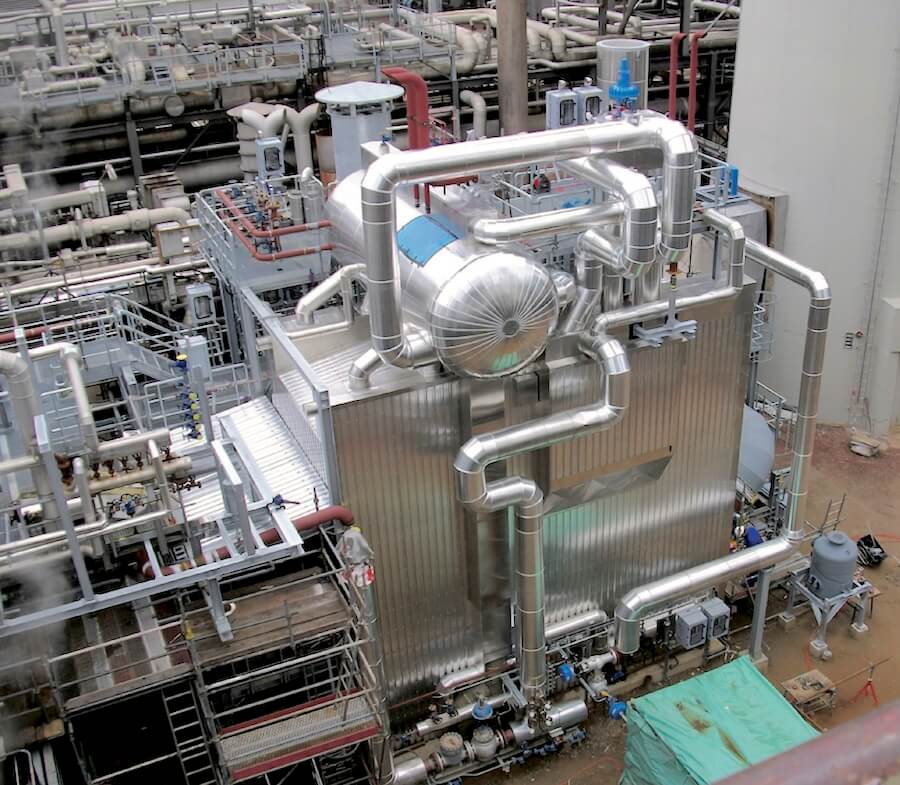

- Single-drum-water tube boilers for high performances and parameters

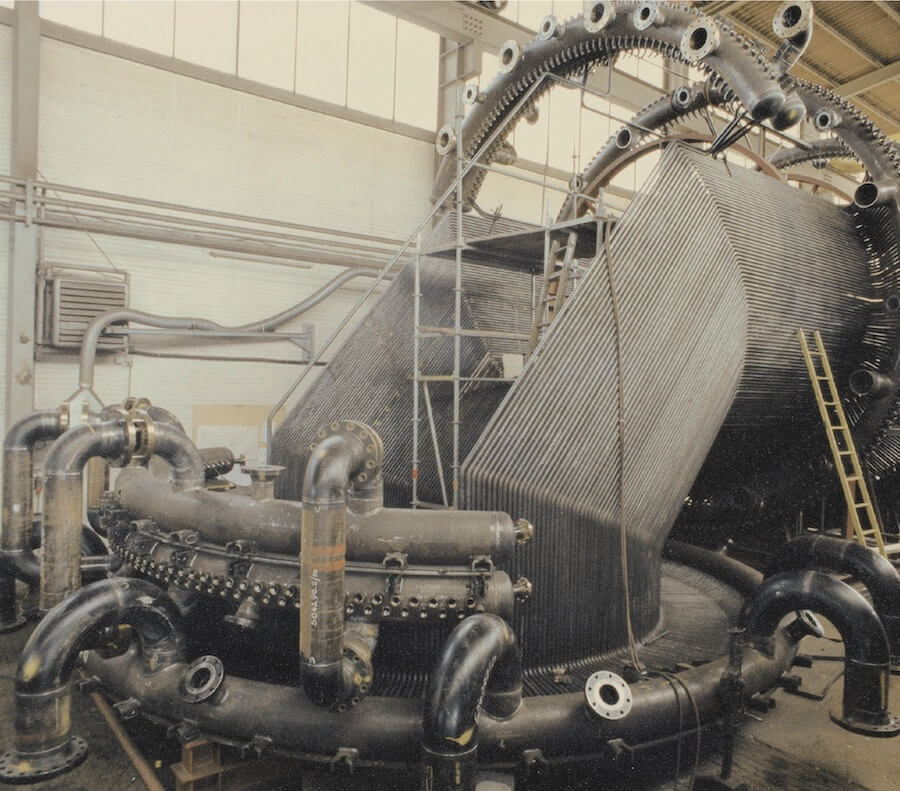

- Two-drum water-tube boilers for medium steam parameters

- Smoke tube boilers with cooled or dry combustion chambers

- Waste heat boilers for gas turbines, motors and thermal processes

- Hot water boilers in water tube design with forced water flow

Steam output range:

- 5 to 150 t/h steam load with live steam parameters of up to 120 bar / 550 °C

- Some cases make alternative parameters possible

Frequent applications:

- Live steam production for steam turbine operation

- Saturated and superheated steam supply for industrial processes

- Hot water delivery for factories and district heating