Energy Solutions

Individual solutions with high efficiency rates

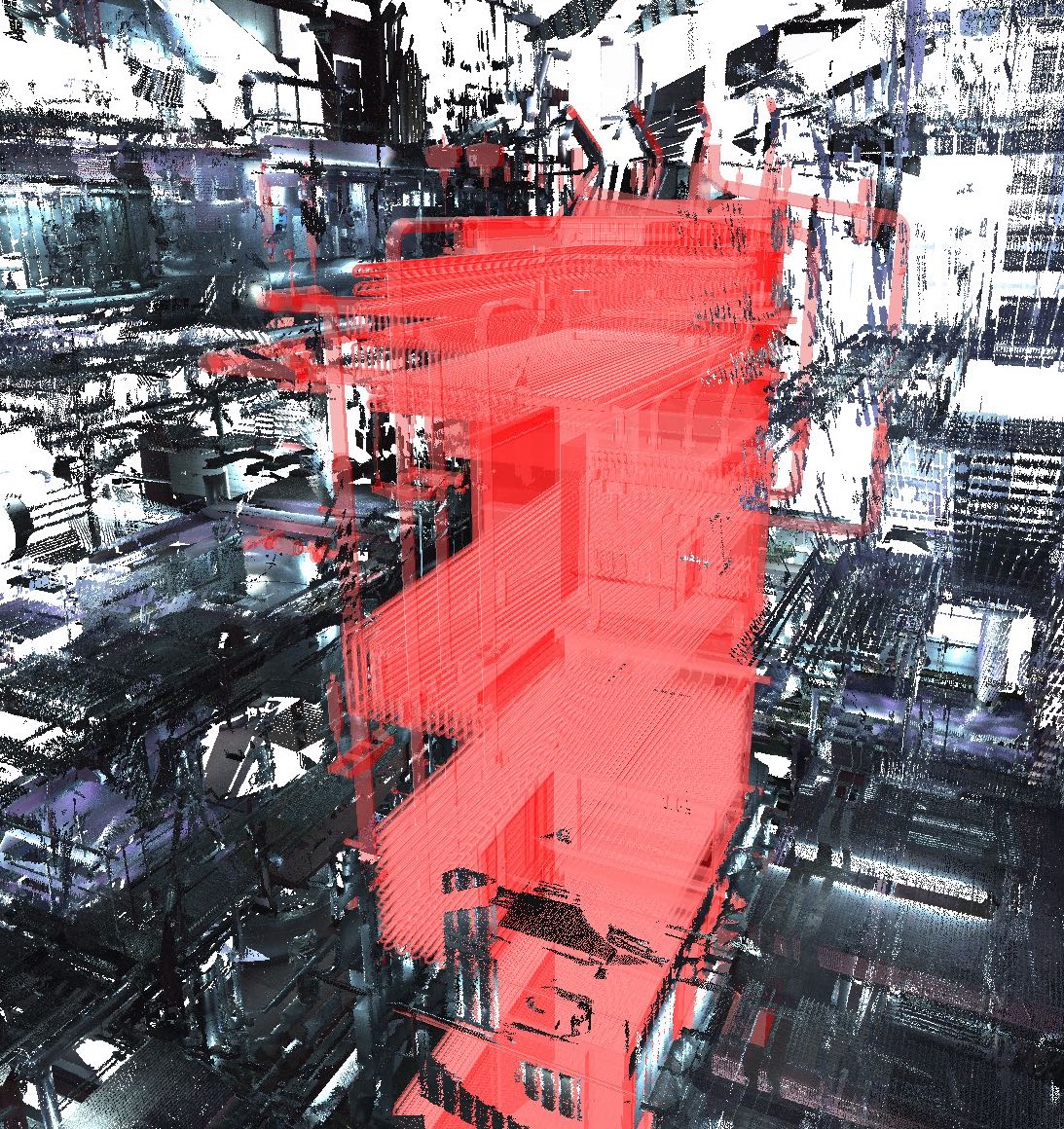

We offer a wide range of production possibilities meeting our clients’ individual requirements and application areas. At our facilities in Husum we design, engineer and manufacture boiler systems and entire plants. We specialise on individual solutions.

Short communication channels between our engineering and production departments and our excellent quality management guarantee products of the highest quality. Our highly skilled personnel will find the best solution for you.